Which type of solar panel does SolarXgen use?

The main solar panel types

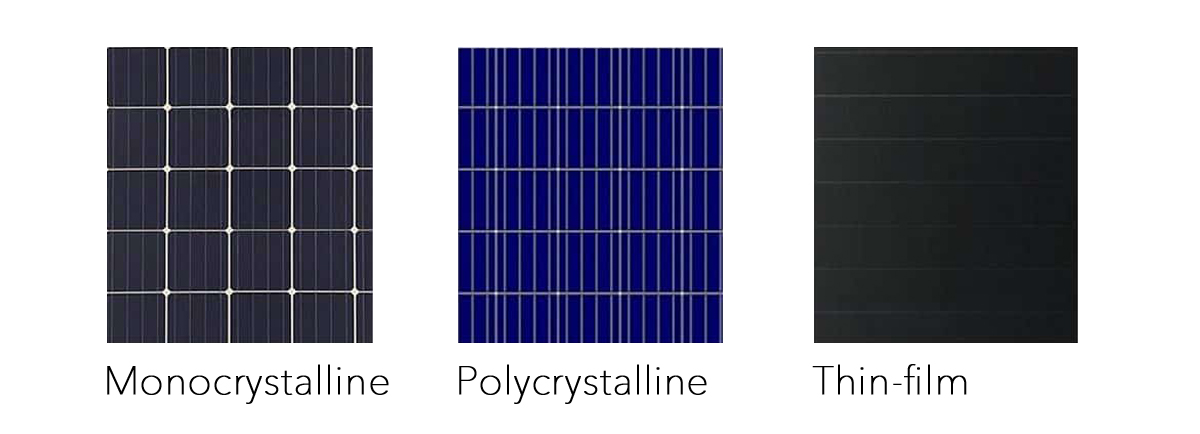

Majority of solar panels in production today fit into one of 3 types – monocrystalline, polycrystalline (multi-crystalline), and thin-film. The differences between them vary in several ways including how they are manufactured, how they look, what they cost, how efficiently they perform and to which installations they would best suit.

What is the most common material that solar panels are made of?

To produce electricity, solar cells are made from a semiconducting material that converts light into electricity. The most common material used as a semiconductor during the solar cell manufacturing process is silicon.

Monocrystalline and polycrystalline solar panels

Monocrystalline and polycrystalline solar panels both have cells made of silicon wafers. To build a monocrystalline or polycrystalline panel, wafers are assembled into rows and columns to form a rectangle, covered with a glass sheet, and framed together.

The difference between Monocrystalline and polycrystalline solar panels is the composition of the silicon itself. Monocrystalline solar cells are cut from a single, pure crystal of silicon whereas polycrystalline solar cells are composed of fragments of silicon crystals that are melted together in a mold before being cut into wafers.

Thin-film solar panels

Unlike monocrystalline and polycrystalline solar panels, thin-film panels are made from a variety of materials. The most prevalent type of thin-film solar panel is made from cadmium telluride (CdTe). To make this type of thin-film panel, manufacturers place a layer of CdTe between transparent conducting layers that help capture sunlight. This type of thin-film technology also has a glass layer on the top for protection.

Thin-film solar panels can also be made from amorphous silicon (a-Si), which is similar to the composition of monocrystalline and polycrystalline panels. Though these thin-film panels use silicon in their composition, they are not made up of solid silicon wafers. Rather, they’re composed of non-crystalline silicon placed on top of glass, plastic, or metal.

Lastly, Copper Indium Gallium Selenide (CIGS) panels are another popular type of thin-film technology. CIGS panels have all four elements placed between two conductive layers (i.e. glass, plastic, aluminium, or steel), and electrodes are placed on the front and the back of the material to capture electrical currents.

Appearance

Monocrystalline solar panels

Monocrystalline solar panels have black appearance to their cells because of how the light interacts with the pure silicon crystal cells.

The back sheet of the Monocrystalline solar panel will most often be black, silver or white, while the metal frames are typically black or silver.

Polycrystalline solar panels

Unlike monocrystalline solar cells, polycrystalline solar cells tend to have a bluish hue to them due to the light reflecting off the silicon fragments in the cell in a different way than it reflects off a pure monocrystalline silicon wafer.

Similarly to monocrystalline, polycrystalline panels have different colors for back sheets and frames. Most often, the frames of polycrystalline panels are silver, and the back sheets are either silver or white.

Thin-film solar panels

Thin film panels main differentiating factor is most often how much slimmer than other panels they can be. Up to 350 time thinner!

These solar panels can come in either blue or black hues, depending on what they’re made from.

Cost

Monocrystalline solar panels

Due to the process involved to manufacture Monocrystalline solar panels, known as the Czochralski process which is energy intensive and results in wasted silicon (that can later be used to manufacture polycrystalline solar cells), they tend be the most costly to produce.

Polycrystalline solar panels

Polycrystalline solar panels are typically cheaper than monocrystalline solar panels to produce. This is because the cells are produced from silicon fragments which allows for a much simpler cell manufacturing process which the end user ultimately benefits from down the line.

Thin-film solar panels

Thin film solar panel costs vary depending on what they are made from. CdTe is generally the cheapest type of solar panel to manufacture, while CIGS solar panels are much more expensive to produce than both CdTe or amorphous silicon. As thin film solar panels are much easier to manouver, it can be much easier and less labour intensive to install.

Production

Monocrystalline and polycrystalline solar panels

Monocrystalline Solar panels tend to have the highest efficiencies and power capacity often reaching efficiencies higher than 20 percent, while polycrystalline solar panels usually have efficiencies between 15 to 17 percent.

Monocrystalline solar panels generate more power not just due to their efficiency but because they also come in higher wattage modules too. With more than 300 watts (W) of power capacity, some Monocrystalline solar panels reach more than 350 W whereas Polycrystalline solar panels, on the other hand, tend to have lower wattages.

Monocrystalline and polycrystalline solar panels can be the same size, both types of solar panels tend to come with 60 silicon cells each, with 72 or 96 cell variants (usually for large-scale installations). But even with the same number of cells, monocrystalline panels are capable of producing more electricity.

Thin-film solar panels

Thin-film solar panels tend to have lower efficiencies and power capacities than monocrystalline or polycrystalline varieties. Efficiencies will vary based on the specific material used in the cells, but they usually have efficiencies closer to 11 percent. Generally speaking, the power capacity per square foot of monocrystalline or polycrystalline solar panel will exceed thin-film panel technology.

So which panels do we, SolarXgen, use and why?

To ensure our partners receive the best ROI we use polycrystalline solar panels due the fact that although they may have a slightly lower efficiency when compared with of monocrystalline solar panels, the cost is much lower to procure and install. In some cases to where meeting output demands, a few more panels may be required, it still works out to be more cost effective to use polycrystalline solar panels.

Looking to the future, we are starting to see a shift in the cost of manufacturing monocrystalline solar panels. With lower production costs improving ROI for our clients, we expect monocrystalline solar panels will soon become a bigger role player and possibly the main stream module type as it has a higher efficiency then polycrystalline solar panels.

| Solar panel type | Advantages | Disadvantages |

| Monocrystalline | High efficiency/performance | Higher costs |

| Polycrystalline | Low cost | Lower efficiency/performance |

| Thin-film | Portable and flexible

Lightweight |

Lowest efficiency/performance

|